Online Manual Handling Course

This online Manual Handling training supports all those who work in a role that will involve pushing, pulling lifting or undertaking any other movement of objects, and helps business owners or managers meet their health and safety responsibilities.

Poor manual handling techniques can lead to a variety of painful musculoskeletal disorders and is one of the largest causes of long-term sickness absence across all UK industries. Promoting good manual handling practice improves workplace safety and reduces individual absence and business costs.

Offering a verifiable, CPD-accredited certificate, this fully online Manual Handling course provides the knowledge needed to work and stay safe. The certificate also provides key evidence of training for retention in your safety records.

Course Content

UNIT 1 | INTRODUCTION

The first learning unit focuses on what manual handling is, highlighting risks arising from poor lifting and handling practice, and details the duties and responsibilities of employers and employees.

UNIT 2 | PHYSICAL CONCERNS

In this second learning unit builds an understanding of the musculoskeletal system, including explaining common disorders and introducing ways to prevent these.

UNIT 3 | RISK ASSESSMENT

In our third learning unit, we introduce the importance of risk assessments – what a risk assessment is, when it is needed, and helps develop the skills to undertake them.

UNIT 4 | SAFE LIFTING TECHNIQUES

Our final unit builds knowledge of how to undertake common workplace lifts safely, e.g. lifting from height, lifting from the ground, pushing, pulling, and team lifts.

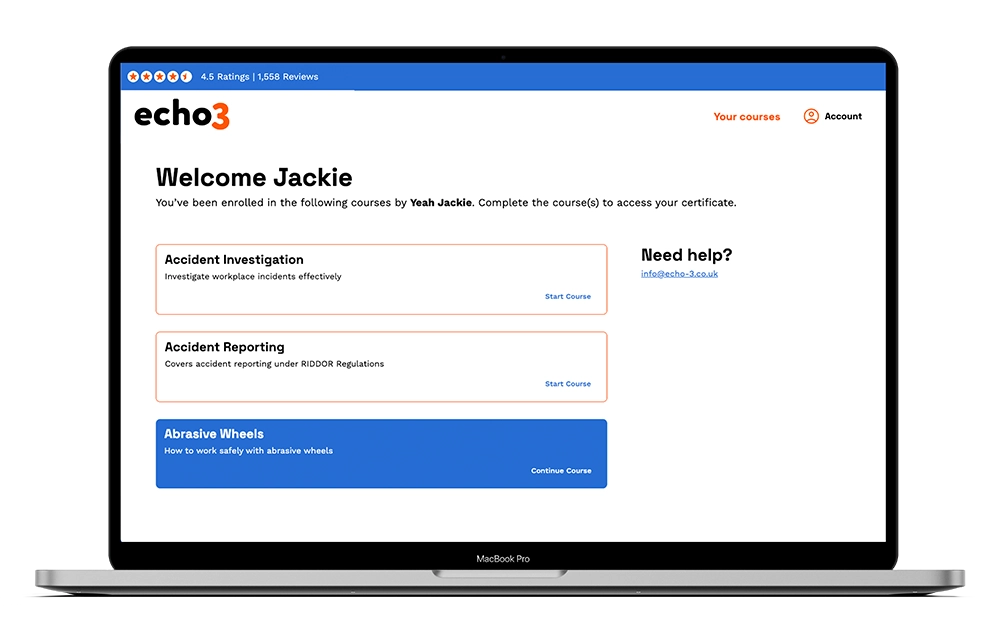

Manual Handling Certificate

Download and Print Your Certificate

- Written in compliance with the Manual Handling Operations Regulations 1992

- Developed by qualified health and safety professionals Accredited by CPD – learn more about CPD here

- Last Updated November 2023

- To gain the certificate you must complete the assessment which involves 20 questions.

- You can access our LMS any time to reprint certificates, check and set pass marks and act as proof of a commitment to ongoing legal compliance.

- The online Manual Handling certificate is valid for 3 years.

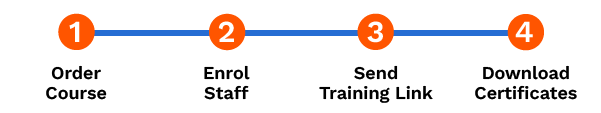

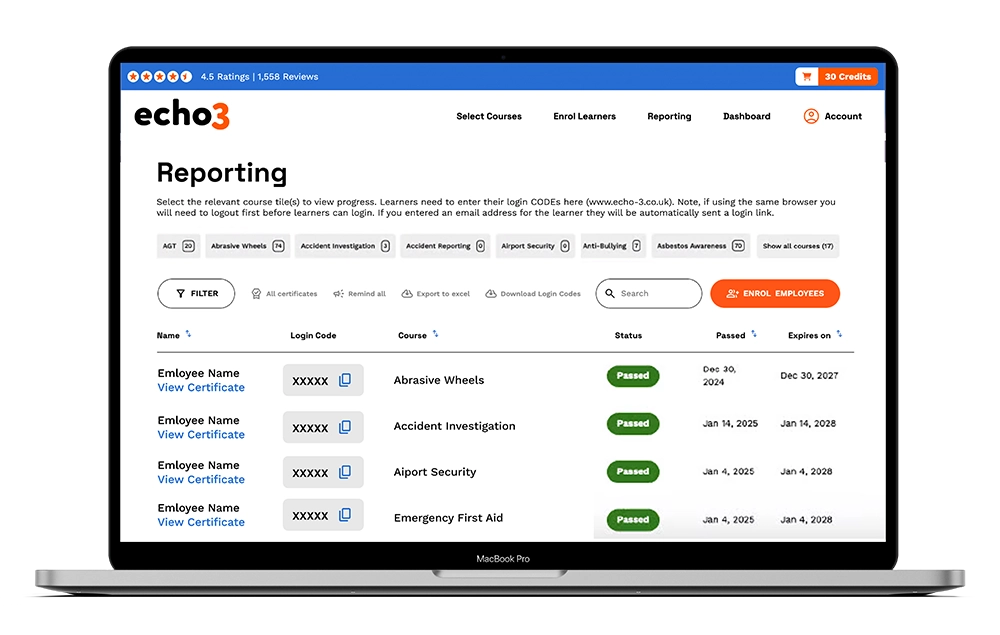

How to use the Echo3 Platform

Individual Learners

Benefits for Individuals

-

Engaging video-based content

-

Learner dashboard included

-

Instant access after payment

-

Free course retakes

-

Shareable digital certificate

QR Code Certificate

QR Code Certificate

Bulk Buying Discounts

10 Courses

50 Courses

100+ Courses

Course Preview

Echo3 courses include engaging motion-graphic video content, with full english subtitles

Who should take the course ?

This online Manual Handling course is designed for staff at all levels in your organisation who are in roles where moving, lifting, or carrying may be part of their work duties, however infrequently.

This includes professional, trade, technical and domestic / housekeeping staff – especially those within the Hospitality industry, Transport, Retail, Construction, Healthcare, Social and Child Care, Agricultural, Manufacturing, Cleaning, and any Warehouse roles.

What are the course objectives?

- Provide the learner with an understanding of manual handling risks arising from their activities.

- Increase individual competence in identifying, assessing, and addressing hazards when undertaking lifting and handling, in order to reduce injuries at work and sickness absence.

- Provide employers with an effective solution to appropriately train staff on moving and handling best practice, and provide evidence of training in line with UK regulations.

What are the learning outcomes?

On successful completion of this Manual Handling training course, learners will:

- Know what manual handling injuries are, and identify potential common causes.

- Recognise the risks arising from poor moving and handling practice, and understand symptoms of musculoskeletal disorders.

- Understand how to assess the risks arising of any manual handling activity.

- Determine procedures required to safely conduct common lifts, e.g. Team lifts; Pushing & Pulling; Lifting from heights.

- Be able to identify appropriate mechanical aids for a task and understand their purpose

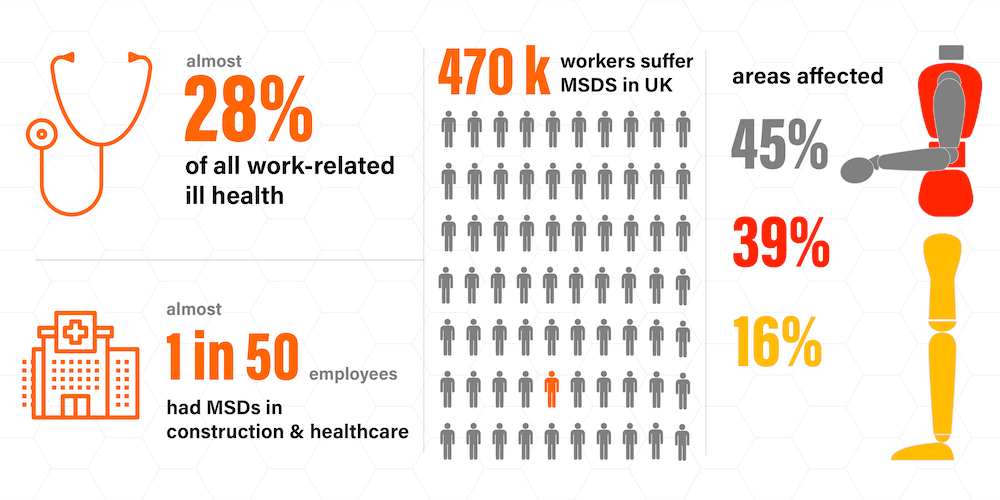

What is the cost of poor Manual Handling?

Musculoskeletal (MSK) disorders account for 28% of all work-related ill-health. This includes the range short term injuries such as sprains and cuts, and long-term issues such as broken bones, as well as impact on an individual’s mental health. The Office of National Statistics estimates 149.3 million working days were lost to sickness and injury in 2021/22.

In the UK each case of ill-health causes on average £19,000 (2018/19) of economic damage spread across the individual, employers, and the government. In total ill-health costs employers £3.2bn, with a significant proportion of cost arising due to poor manual handling practices within the workplace.

Manual handling training helps mitigate costs of absence due to poor moving and handling by reducing the risk of injuries at work.

What is Manual Handling?

‘Manual handing’ is defined by the Health & Safety Executive (HSE) as the act of ‘transporting or supporting a load by hand or force’. This covers any kind of moving, lifting, pulling, putting down or carrying loads.

If done incorrectly, poor moving and handling techniques increase the chance of both injury and musculoskeletal (MSK) disorders, including significant damage to bones, tendons, joints, ligaments, and muscles.

Legal Requirements

Duties arising under the Manual Handling Regulations (Amended 2002) require employers to take all ‘reasonably practicable’ steps to reduce risks from lifting activities to an ‘appropriate’ level.

Practically this means:

- Assessing the risks from lifting and manual handling

- Eliminating manual handling activities where possible

- Reducing the risks from the remaining activities

- Periodically reassessing risks, including gathering staff feedback

Under The Management of Health & Safety at Work Regulations 1999, all organisations with 5 or more staff must document these risk assessments and maintain safety records – this including records of training.

Completion of this training by staff helps you and your business meet your duties under the Health & Safety at Work Act 1974, and the Manual Handling Operations Regulations 1992, and as amended in 2002, in a cost-effective way.

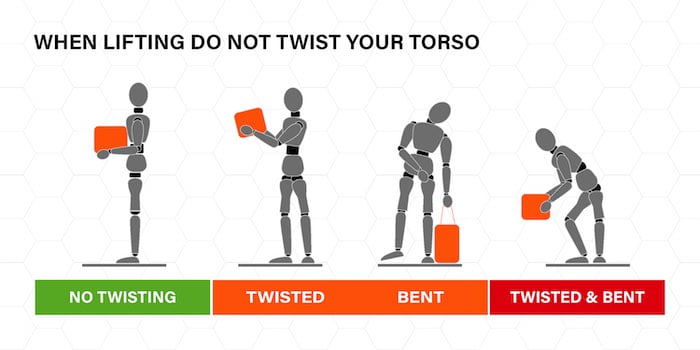

Lifting Tips

Is online Manual Handling Training effective?

Although moving, handling, or lifting are physical activities, knowing how to do so safely is not difficult learn. The key to lifting safely is knowing how to assess a task and then using appropriate moving and handling techniques.

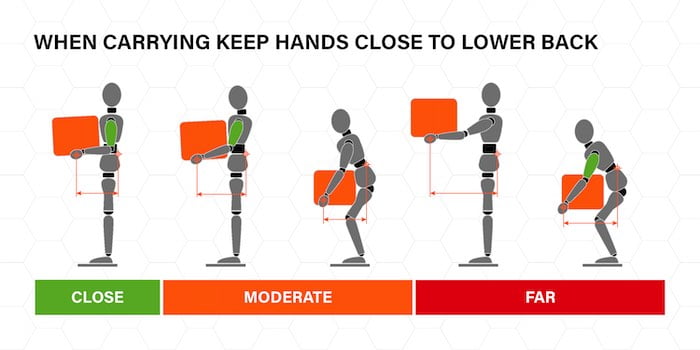

This means learning and understanding the eight (8) principles of safe lifting. These are:

- Assess the task, the individual, the load and the environment

- Have a broad stable base,

- Bend your knees

- Keep you back straight

- Have a secure firm palmer grip

- Keep your arms close to trunk

- Weight close to your centre of gravity

- Turn feet in direction of travel

This online Manual Handling course provides the knowledge needed to ensure all those in your organisation know the importance of moving and handling safely and reduce the risk of workplace injuries and absence.

Do you need Manual Handling Training?

First, think about these questions.

- Do individuals require to move or carry objects frequently?

- Do they need to move or carry objects a long way?

- Does their moving, handling or lifting require reaching up high or bending down?

- Does their moving, handling or lifting require twisting, flexing or any other awkward postures?

- Has anyone in your team experienced musculoskeletal disorders or related absence due to work activities previously?

- Are team lifts required?

If any of your answers are ‘yes’, then, Manual Handling training is likely appropriate. The extent of training should be proportional to the assessed risk.