LADDER SAFETY CHECKLIST

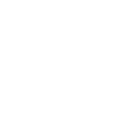

In this Ladder safety article we take a look at the different types of ladders and a checklist of general rules you should we aware of. All work involving ladders must be planned so that a risk assessment can be carried out. If the work you want to do has not gone through a risk assessment, don’t do the work until an assessment is done. Staff will also need appropriate ladder safety training.

WHEN TO USE LADDERS

Ladders should only be used as work equipment where a risk assessment shows the use of other work equipment is not justified. The Work at Height regulations don’t ban ladders but do require that they be used with careful consideration.As a guide, use a ladder where the work will take less than 30 minutes, where the risk is low or in other words, where the nature of the work makes a fall unlikely. And remember to only use ladders for ‘light work’ – ladders are not suitable for strenuous or heavy work.Two or more separate ladders must be provided when ladders are the only means of access or egress from a work area that has over 25 employees.SAFE LADDER USE

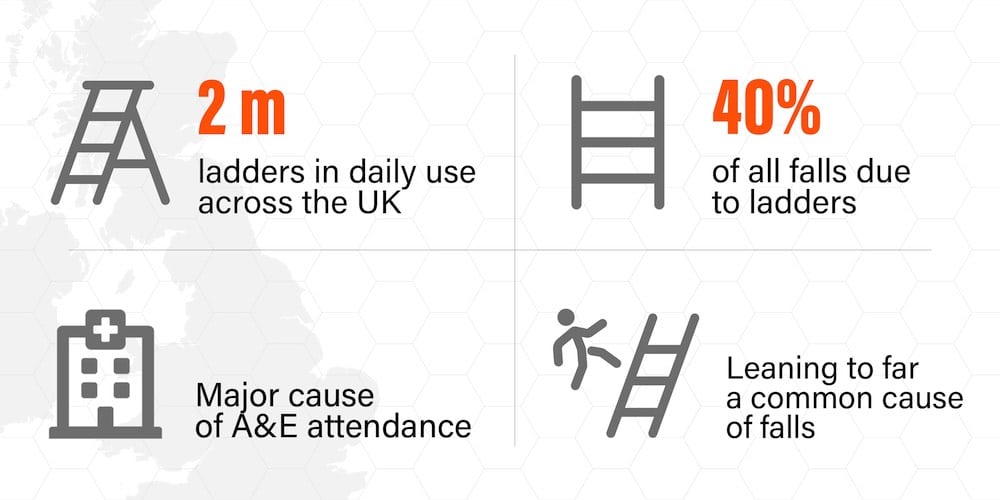

1. When climbing, use a three-point climb.A three-point climb is where you always have both feet and at least one hand or both hands and one foot on the ladder. Two feet and your body resting or touching the ladder qualifies as three points of contact.

2. Always face the front of the ladder and keep hands on side rails at all times when climbing. Keep weight centered and do not straddle the ladder.The belt-buckle rule is a good way to ensure that you are centered; keep your belt buckle between the side rails of ladder at all times and you will reduce your risk of falling.

LADDER INSPECTIONS

Documented ladder inspections should be carried out by a nominated competent person within your company. Although these are carried out weekly, every employee should do their own inspection before using a ladder.Check for cracks in stiles, rungs, corrosion, distorted or bent stiles or rungs and contaminants like paints, acids or oils. Also check for damaged or missing rubber feet and damaged locking mechanisms.LADDER WEIGHT CATEGORIES

The different categories of ladders are determined by their duty rating, which is based on their maximum weight capacity. The ‘Maximum Static Vertical Load’ is a more useful measure and gives a more accurate guide to relative strengths.Industrial Duty Class 1 ladders are designed for a Maximum Static Vertical Load of 175 kilograms.Trade Duty previously known as Class 2, but now EN131 ladders are designed for a Maximum Static Vertical Load 150 kilograms.Domestic Duty Class 3 ladders are designed for a Maximum Static Vertical Load of 125 kilograms.When calculating your total weight, be sure to add the weight of your PPE, tools, and supplies to your own weight. Always check the manufacturer’s label for the maximum load.GENERAL LADDER SAFETY

When working on a straight ladder, do not reach further than arms-length from the ladder. Doing so could throw you off balance and put you a risk. Ensure that the ladder remains in position by securing it at the top or bottom.Alternatively, a second worker must hold the ladder at the bottom and act as a spotter. Keep in mind that ladders should never be placed horizontally and used as a runway. Finally, fall protection should be provided if a risk assessment shows that there is a significant risk of falling.TYPES OF LADDER

StepladdersStepladders must not be used as straight ladders. They should be fully spread, placed on a level surface and locked open when in use.You can use stepladders for light work under 10 kilograms and for up to half an hour. Do not work off the top two steps unless there is a safe handhold attached to the steps.As we mentioned earlier, even a fall from a small heights such as a stepladder could put you at risk of serious injury.Metal StepladdersWhen inspecting metal stepladders, make sure to keep an eye out for any corrosion of the metal. If there is any damage or if the rubber feet are missing, do not use it. Also remember to avoid using a metal stepladder near exposed electrical wires and equipment.

Fibreglass LaddersExcessive heat, solvents and corrosives can deteriorate or crack fibreglass stepladders, so try to avoid using these elements when using a fibreglass ladder. In the event that a fibreglass ladder is exposed to heat or chemicals, it is important to take that into consideration when performing an inspection.

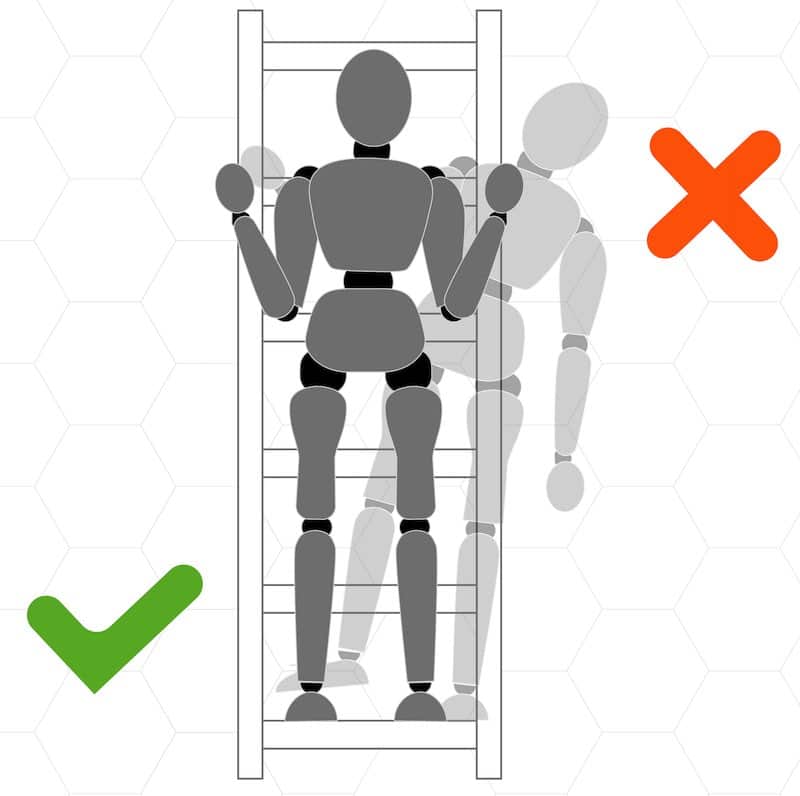

Straight LaddersEmployees shall not work higher than the third rung from the top on straight or extension ladders. If you work higher than the third rung it can cause the bottom of the ladder to slide away from you, as all the weight is at the top.Straight ladders are required to extend at least 1 metre above the landing. If the ladder extends 1 metre above the platform, it gives clear access to get off the ladder. The 4 to 1 rule should be followed for the use of straight ladders as well. For every 1 metre out, you should go 4 meters up. That will give you a safe angle of ascent and descent.

Roof LaddersOn most sloping roofs, suitable roof ladders or crawling boards will be essential, in addition to edge protection. Where a high standard of edge protection is provided, it may be safe to work without a roof ladder.This may apply if the pitch is shallow and the surface provides a particularly good foothold. The decision in each case should be based on a risk assessment; and should be designed and fabricated to be fit for purpose. Roof ladders should be strong enough to support workers when spanning the roof covering.They should be long enough to span the supports and secured and placed to prevent accidental movement. The anchorage at the top of the roof ladder should be by some method which does not depend on the ridge capping, as this is liable to break away from the ridge.The anchorage should bear on the opposite slope by a properly designed and manufactured ridge iron or be secured by other means. Eaves and gutters should not be used as a footing or to support a roof ladder as they are fragile and could easily be damaged.

LADDER STORAGE AND MAINTENANCE

Straight ladders should be hung horizontally and supported every two meters. Nails or hooks can be placed on the sides of storage areas so that the ladders can be stored properly. All ladders should be stored in a well-ventilated area away from extreme heat or cold.Extremes in temperature cause the material in the ladder to expand or contract, thus causing cracks in the material. Avoid storing items on top of ladders.This increases the load on the ladder, and the stored items could fall off and hurt someone. Clean and lubricate the ladder’s moving parts, keep rungs and steps free of oil and dirt to prevent slips, and when transporting, remember to make sure both ends are secure to prevent movement.LADDER PLACEMENT AND LOCATION

The placement and location of ladders is extremely important.Only use ladders and stepladders in a place where they cannot be struck by vehicles or equipment, and use barriers if necessary. Keep them away from doors or windows, and where this is not possible, inform other workers not to open windows or doors.Make sure they are in a location where pedestrians cannot walk under or bump into them, and again, use signs or barriers if necessary. As far as physical locations go, make sure ladders are set up in a place where all locking devices and extensions can be properly engaged.When working near weak surfaces, a stand-off device can be used to avoid damaging those weak surfaces like glass or plastic guttering. And finally, make sure the surface you are working on is clean and level.When placing ladders the should go out 1 metre for every 4 metres they go up.

SECURING A LADDER

When securing the ladder, tie it to a suitable point, ensuring both stiles are tied. Where this is not practical, use an effective stability device and as a last resort, foot the ladder.Avoid side loading. This is when you have to turn to the right or left in order to do your work. Instead, always have the ladder facing the direction of your work. Ladders can be tied at the top, half-way down and near the base.SUMMARY

To review the Ladder safety checklist – portable ladders may be used if more suitable equipment is not justified.A risk assessment must be performed before using the ladder, and make sure you do a visual inspection before starting any work. Use the right ladder for the right job, and use it properly. Keep the amount of time you spend on a ladder to under thirty minutes and keep the load light.Face the ladder and use both hands when ascending or descending, do not over-reach, and do not work off the top two steps. The principles of ladder safety are pretty straightforward, but it is important you use those principles every time you use a ladder.After reading the ladder safety checklist if you wish to provide this as training to your staff visit our Ladder Safety course or Working at Height course pages.