Abrasive Wheels Course

The Echo3 online Abrasive Wheels course helps individuals understand the hazards and best practices associated with these tools, helping to ensure safer work environments and compliance with regulations.

Nearly half of all accidents involving abrasive wheels arise because of either unsafe system of work or operator error.

Training those who operate abrasive wheels will reduce the risk of incidents and demonstrate compliance with UK Health & Safety Regulations.

This CPD-Accredited Abrasive Wheels online course is based on best practice guidance from the Health and Safety Executive (HSE).

Coures Content

UNIT 1 | Underpinning Knowledge

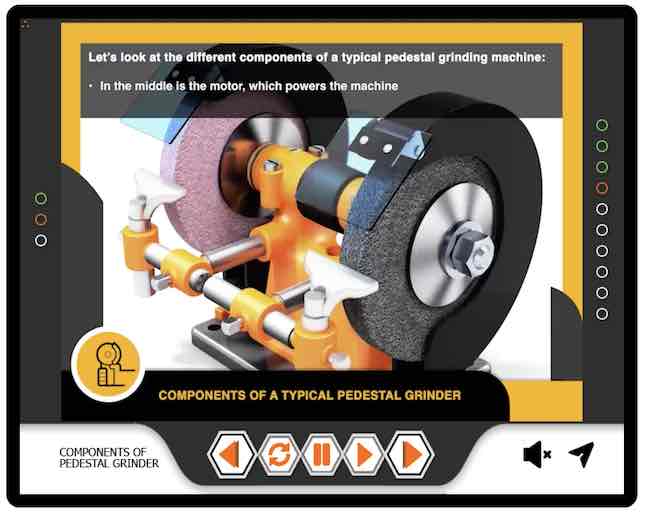

This first unit builds fundamental knowledge of abrasive wheels, outlining what they are and how they work. We look at the functions of the different components used with abrasive wheels, and the labelling system that helps workers select the right wheel for the job at hand. Finally, we explore the legal and moral responsibilities of employers and employees to ensure their safe operation, to avoid harm to themselves and those around them.

Specifically, we will cover:

- What is an abrasive wheel?

- How do abrasive wheels work?

- Different types of abrasive wheel

- Components of a typical pedestal grinding

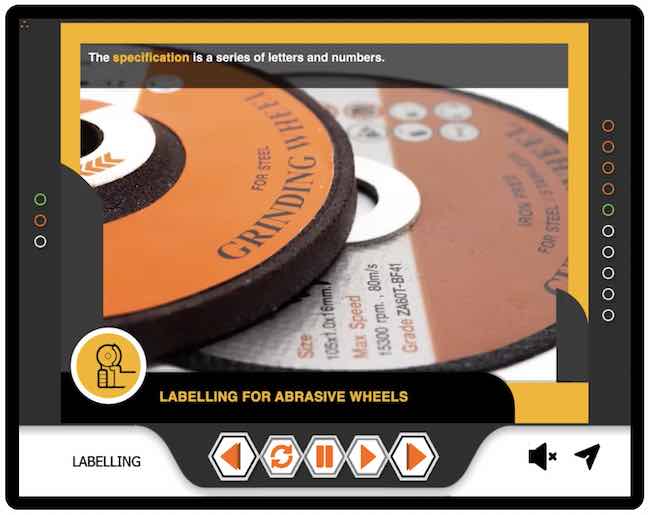

- Labelling abrasive wheels

- Essential Law

- Employer Duties

- Employee Duties

UNIT 2 | Hazards & Safety Controls

In Unit 2 we focus on identifying and addressing hazards and risks of injury arising from working with abrasive wheels. This unit also explains the appropriate safety controls required to reduce the possibility of an accident occurring, including the effective workspace management.

Specifically, we will cover:

- Abrasive wheel hazards and how to identify them

- How to check abrasive wheels for damage

- Safety Controls – moving wheels

- Safety Controls – storage

- Choosing the correct wheel

- Setting up the workspace

- Work rests

- Wheel guards and shields

- Mounting the wheel

- Beginning work

- Truing and Dressing

- PPE

Abrasive Wheels Course Certificate

Download and Print Your Certificate

- Written in compliance with the UK HSE Abrasive Wheels Guidance

- Developed by qualified health and safety professionals

- Accredited by CPD – learn more about CPD here

- Last Updated June 2024

- To gain the certificate learners must complete the assessment which involves 15 questions.

- The online Abrasive Wheels certificate is valid for 3 years.

Course Preview

Echo3 courses include engaging motion-graphic video content, with full english subtitles

Reviews

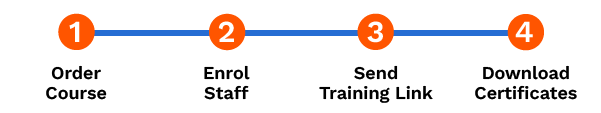

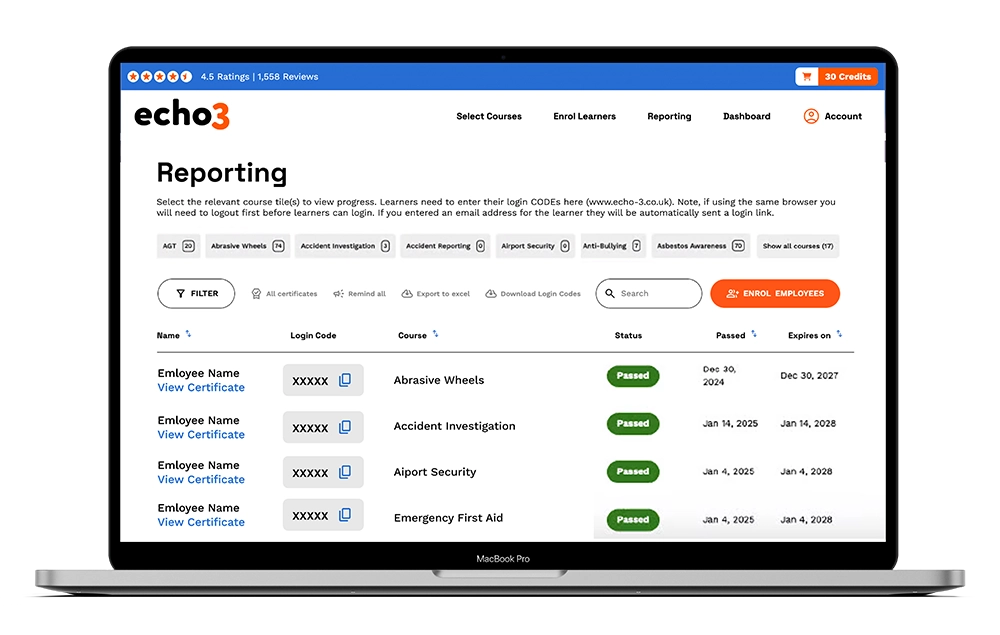

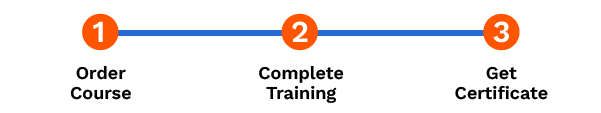

How to Get Certified in 3 Steps

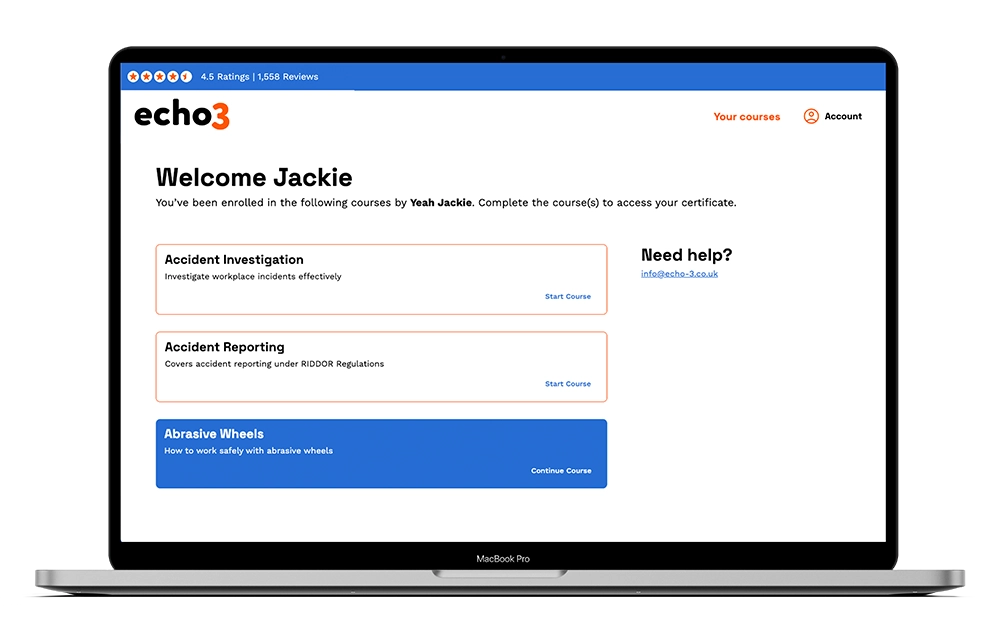

Individual Learners

Benefits for Individuals

-

Engaging video-based content

-

Learner dashboard included

-

Instant access after payment

-

Free course retakes

-

Shareable digital certificate

QR Code Certificate

QR Code Certificate

Bulk Buying Discounts

What are the learning outcomes?

The Echo3 Abrasive Wheels training is designed to equip participants with the appropriate knowledge to use and handling abrasive wheels safely. Key learning objectives include:

The Echo3 Abrasive Wheels training is designed to equip participants with the appropriate knowledge to use and handling abrasive wheels safely. Key learning objectives include:

Understanding Abrasive Wheels, participants gain an understanding of what abrasive wheels are, the different types available, and their applications.

Hazards and Risks, recognise the potential hazards associated with abrasive wheels, participants learn to identify risks and understand the importance of safety measures.

Legal and Regulatory Compliance, the eLearning course covers the relevant legislation, regulations, and best practices that govern the use of abrasive wheels, ensuring compliance.

Selection and Inspection, participants will learn how to choose the right abrasive wheel for specific tasks and how to inspect them for defects and damage.

Safe Handling and Operation, understanding safe handling procedures, including mounting, and dressing abrasive wheels, as well as the correct operating techniques to prevent accidents.

PPE and Control Measures, the training emphasises the importance of personal protective equipment (PPE) and control measures to mitigate risks.

Who is this Abrasive Wheels course for?

The Echo3 online Abrasive Wheels course is valuable for all those who work with or around abrasive wheels in various industries. This includes, but is not limited to:

Machine Operators, individuals directly involved in using abrasive wheels, such as grinders, cut-off saws, and sanders, should take the course to ensure they understand safe operation.

Supervisors and Managers, those overseeing work processes involving abrasive wheels can benefit from the course to improve their understanding of safety practices and effectively manage teams.

Safety Professionals, responsible for maintaining safe workplaces should take the course to enhance their expertise in abrasive wheel safety.

Maintenance Personnel, responsible for maintaining and inspecting abrasive wheel equipment should receive training to ensure proper care and functionality.

Anyone at Risk, even if not directly working with abrasive wheels, individuals who may be in the vicinity of equipment using abrasive wheels should understand the associated risks and safety measures.

What are the benefits of Abrasive Wheel training from Echo3?

Taking the Echo3 online Abrasive Wheels course offers several benefits for individuals and employers;

Taking the Echo3 online Abrasive Wheels course offers several benefits for individuals and employers;

Risk Reduction, understanding the hazards associated with abrasive wheels and how to mitigate them is vital. The course equips individuals with the tools to identify and address potential risks, ultimately reducing workplace accidents and injuries.

Legal Compliance, completing the course ensures participants know their legal responsibilities while employers can demonstrate due diligence by retaining completion certificates.

Operational Efficiency, the knowledge gained from the course allows individuals to use abrasive wheels more efficiently, reducing waste and enhancing productivity.

Flexible Learning, the online format of the course allows participants to learn at their own pace and convenience.

What is an abrasive wheel?

Abrasive wheels are used for grinding. They vary in shape and size, and are made from compounds that have been bonded together using various substances.

Abrasive wheels are made using two main types of bonding agent: organic and inorganic.

Wheels with inorganic bonds are often used for precision grinding.

Organic bonding uses material such as resin, rubber and shellac, or other similar binding agents. Wheels with organic bonds are tough and shock resistant. So they are most suited to non-precision applications.

Why is abrasive wheels training required?

The Provision and Use of Work Equipment Regulations (PUWER 98) came into force in 1998.

The primary objective of PUWER 98 is to ensure that work equipment, including abrasive wheels, does not give rise to risks to health and safety, regardless of the work equipment’s age, condition or origin. PUWER 98 applies to all workplaces and work situations subject to the Health and Safety at Work Act 1974.

Under PUWER, employers must conduct risk assessments to ensure that any risks are identified and minimised before commencing work.

To comply with the Regulations your employer must supply you with well-maintained, inspected, and tested tools and equipment that are safe to use and suited to the intended purpose.

Your employer must also ensure you are provided with suitable training. Typically, this will cover:

- Risks

- Labels

- Storage, handling, and transportation

- Wheel inspection and testing

- The functions of all components

- How to assemble wheels correctly

- How to dress abrasive wheels

- How to adjust machines

- The type of personal protective equipment you should wear

Your employer must also provide appropriate personal protective equipment and replace it when damaged or worn out.