LOLER Course

Online LOLER course providing staff with the knowledge needed to work safely.

LOLER refers to the Lifting Operation and Lifting Equipment regulations that came into force in 1998. LOLER aims to reduce the risks to people’s safety from lifting equipment that at work.

The Echo3 LOLER training provides a clear understanding of what LOLER requires, the potential hazards from mechanical lifting equipment and how to reduce the risk.

Knowing the potential dangers from lifting activities will help you and your staff understand why adhering to the LOLER requirements is vital for maintaining a safe workplace.

The course has been designed for everyone working with lifting equipment and supervising those that do.

LOLER Course Content

UNIT 1 – INTRODUCTION TO LOLAR

In this first unit you get to know the LOLER regulation. This is necessary if you either lift at work or supervise those that do.

UNIT 2 – HAZARDS FROM LIFTING

Knowing the potential danger from lifting activities will help you understand why always adhering to the LOLER requirements is vital to your safety at work.

UNIT 3 – PLANNING LIFTING OPERATIONS

An effective Lift Plan is an essential part of LOLER compliance and lifting safely. In this 3rd unit we detail how to plan lifting operations effectively.

UNIT 4 – ROLES AND RESPONSIBILITIES

Knowing who is responsibility for which duties is an essential part of lifting safely. In this 4th unit we cover Roles and Responsibilities, so you know who has responsibilities for what with respect to lifting.

UNIT 5 – BEST PRACTICE

In this 5th unit we outline the best practices you can take which will help ensure each lift is done as safely as possible.

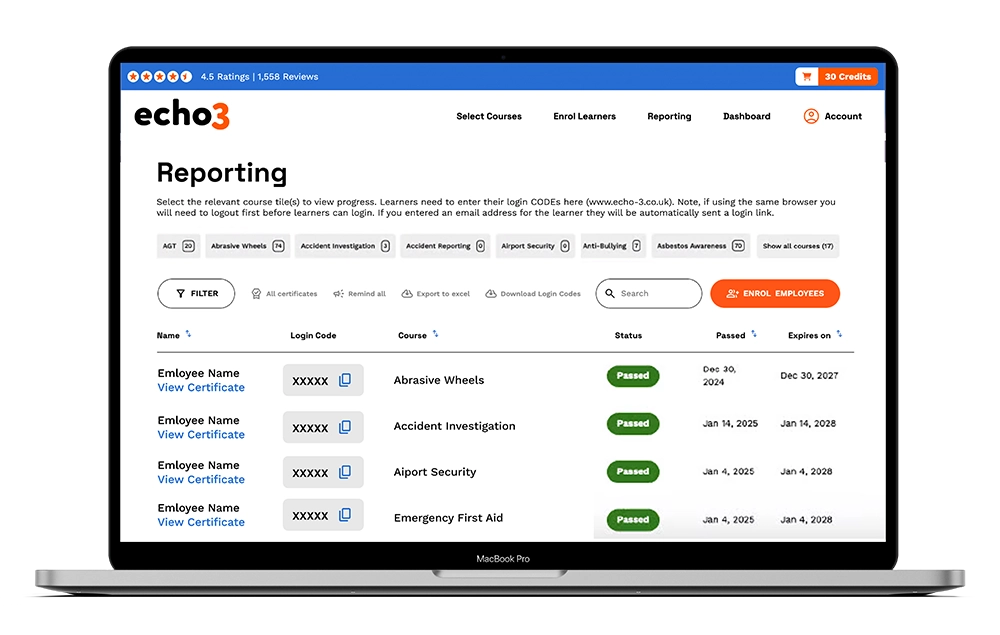

LOLER Course Certificate

Download and Print Your Certificate

- Written in compliance with the Lifting Operations and Lifting Equipment Regulations 1998

- Developed by qualified health and safety professionals Accredited by CPD – learn more about CPD here

- Last Updated June 2025

- To gain the certificate you must complete the assessment which involves 20 questions.

- You can access our LMS any time to reprint certificates, check and set pass marks and act as proof of a commitment to ongoing legal compliance.

- The online LOLER certificate is valid for 3 years.

Course Preview

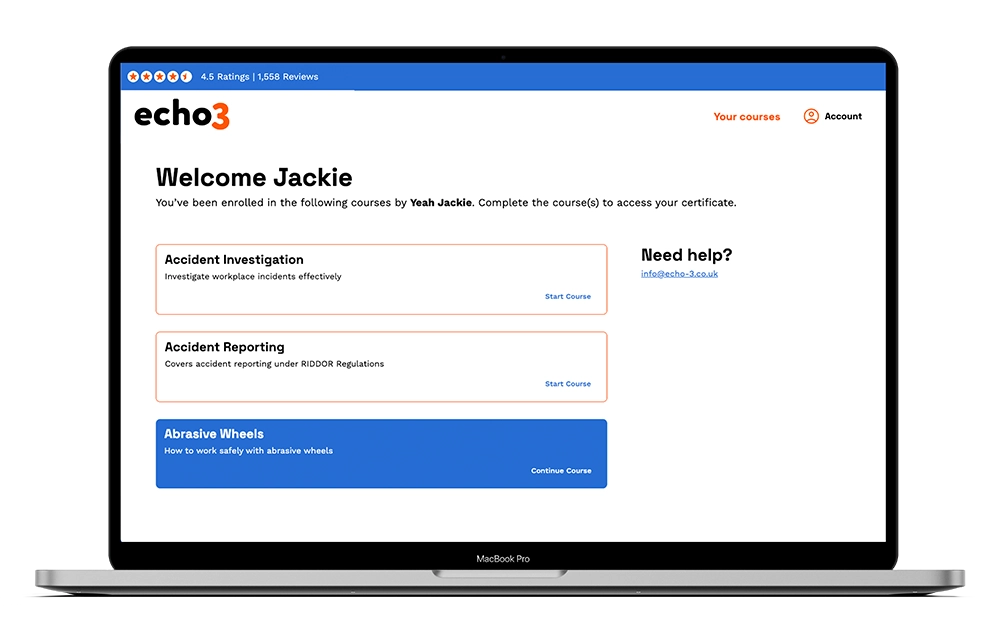

Echo3 courses include engaging motion-graphic video content, with full english subtitles

Reviews

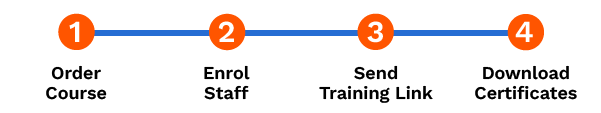

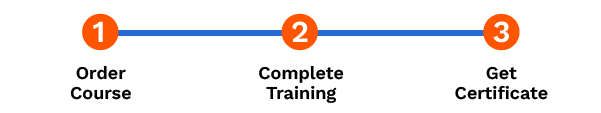

How to Get Certified in 3 Steps

Individual Learners

Benefits for Individuals

-

Engaging video-based content

-

Learner dashboard included

-

Instant access after payment

-

Free course retakes

-

Shareable digital certificate

QR Code Certificate

QR Code Certificate

Bulk Buying Discounts

What are the LOLER learning objectives?

Learning objectives for theEcho3 online LOLER training curse:

Learning objectives for theEcho3 online LOLER training curse:

Understand LOLER Legislation, gain an understanding of the Lifting Operations and Lifting Equipment Regulations 1998 (LOLER) in the UK, including its scope, legal requirements, and key provisions.

Inspection and Maintenance, learn the importance of regular inspections and maintenance for lifting equipment, including documentation and record-keeping to ensure safety and compliance.

Risk Assessment, Develop the ability to assess and mitigate risks associated with lifting operations, including factors like load capacity, environmental conditions, and equipment maintenance.

Operator Competency, understand the need for trained and competent personnel to operate lifting equipment, including relevant qualifications and certification requirements.

Legal Compliance, gain the ability to assess and maintain legal compliance with LOLER regulations, reducing the risk of accidents and potential legal liabilities.

Safe Lifting Best-Practices, acquire knowledge about safe lifting procedures, including load securing, signalling, and communication during lifting operations.

Who should take this LOLER training?

Businesses involved in lifting operations must ensure that their employees are adequately trained in LOLER regulations to maintain a safe and compliant work environment while avoiding legal liabilities.

Businesses involved in lifting operations must ensure that their employees are adequately trained in LOLER regulations to maintain a safe and compliant work environment while avoiding legal liabilities.

An online LOLER course is essential for a wide range of professionals involved in lifting operations, including.

- Equipment Operators, Operators of cranes, forklifts, hoists, and other lifting equipment should take a LOLER course to ensure safe operation, compliance with regulations, and minimise the risk of accidents.

- Supervisors and Managers, those responsible for overseeing lifting operations, including site supervisors and safety managers, benefit from a LOLER course to understand the legal requirements, assess risks, and implement safety protocols.

- Maintenance Personnel, technicians and maintenance workers who service lifting equipment should be trained to ensure proper upkeep, compliance with LOLER requirements, and equipment longevity.

- Health and Safety Professionals, individuals in the field of occupational health and safety, such as safety officers and consultants, can enhance their expertise by taking a LOLER course to better advise and support organizations in compliance and safety practices.

- In summary, anyone involved in lifting operations, from equipment operators to safety professionals should consider taking an online LOLER course to help ensure safety and compliance.

What is LOLER?

LOLER refers to the Lifting Operation and Lifting Equipment regulations that came into force in 1998. This regulation aims to reduce the risks to people’s health and safety from lifting equipment that is provided for use at work.

Lifting equipment is also subject to the requirements of the Provision and Use of Work Equipment Regulations 1998, known as PUWER. We cover PUWER in another course.

LOLER requires that lifting equipment that has been provided for your use at work is:

1. Strong and stable enough for the particular use and marked to indicate safe working loads

2. Positioned and installed to minimise any risks

3. Used safely – so the work must be planned, organised and performed by competent people, and subject to ongoing thorough examination and inspected by a competent person.

What equipment does LOLER cover?

LOLER cover all lifting equipment. The term ‘Lifting Equipment’ includes ‘Lifting Appliances’ and ‘Lifting Accessories’.

What is meant by the term Listing Appliances?

A ‘lifting appliance’, is any mechanical device capable of raising or lowering a load, including attachments used for anchoring, fixing or supporting it.

The regulations cover a wide range of equipment including but not limited to:

- Cranes

- Forklift trucks

- Trolley Jacks

- 2-Post Lifts

- Suspended cradles

- Powered hoists

- Manual hoists

- Beam trolleys

- Sheave blocks

- and Winches

If your employer allows you to use your own lifting equipment, it is also covered by LOLER regulation.

What is meant by the term Lifting Accessories?

A lifting accessory is anything designed to connect a load to a lifting appliance but does not form a part of the actual load.

Examples of Lifting Accessories include:

- wire rope slings

- chain slings

- man-made fibre slings

- hooks and fittings

- swivels

- shackles

- eyebolts

- rigging screws

- wedge sockets; and

- plate clamps

What are the potential hazards from lifting?

The Weather – The weather can affect lifting activities. The effects of rain, snow, ice and wind can all affect how a load must be controlled and handled.

Dropping the Load – This can be caused by the following factors:

- A swinging load

- Failure of lifting equipment

- Failure of a securing point on a load

- The crane or other equipment toppling

A damaged load – This can be caused by the following factors:

- Failure of ropes, chains or slings; and

- Poor slinging techniques due to insufficient planning of the lift

Collisions – The load or lifting lines colliding with or being snagged on other equipment, including power cables. Also a collision with structural equipment such as floodlights can lead to other hazards such as dropped objects.

New Equipment – Using new equipment may be hazardous as although certified it may not always be safe. You may be unfamiliar with how to use it so this may lead to accidents.

What makes lifting equipment illegal under LOLER?

Lifting Equipment can be either Inadequate or Unstable. If either exists, they have the potential to cause people and equipment to be seriously hurt.

All lifting equipment must have the adequate strength and stability for every load that it lifts. Otherwise, it is inadequate equipment and therefore illegal under LOLER.

A load must also be stable while it is being lifted. This is also a legal requirement under LOLER. Obviously do not commence a lift if the load is or may potentially become unstable.

Consider the following points when using lifting equipment.

- Is the lifting equipment adequate?

- Is the lifting equipment itself stable?

- Is the surface the lifting equipment on also stable?

- Is the load secure?

- How will the load be lifted?

- What is the size and nature of the load?