WAREHOUSE SAFETY COURSE

Warehouse operations present extra hazards to staff when compared to most other workplaces. For example, workers are at greater risk of injury from; slips & trips, manual handling, falling objects, hazardous substances and vehicle collisions.

The Health & Safety Act 1974 requires that all warehouse staff receive appropriate safety training, so they are aware of dangers and how to avoid them.

This online Warehouse Safety course provides the knowledge needed to work safety in warehouses and helps employers meet training requirements.

Warehouse Safety Course Content

Unit 1 – Warehouse Safety Legislation

This unit outlines the key health and safety responsibilities of both employers and employees under the Health and Safety at Work Act, specifically in the context of warehouse operations.

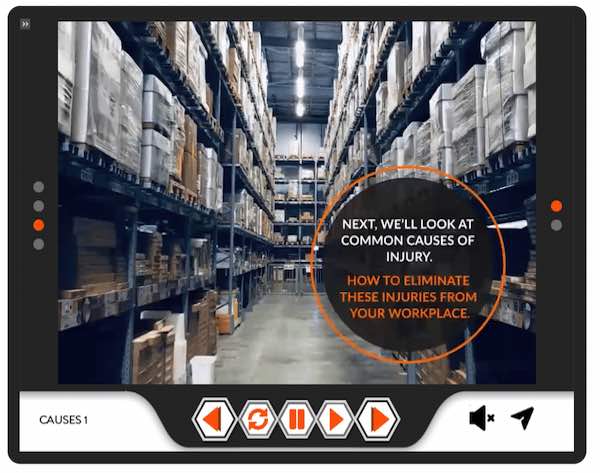

Unit 2 – Common Causes of Warehouse Accidents

This unit begins by explaining the importance of warehouse safety training and highlights common hazards associated with working in warehouse environments.

Unit 3 – Reducing Risks

This unit highlights the most common causes of injuries in warehouse environments and provides practical guidance on how to prevent them.

It covers key hazards such as slips and trips, working at height, manual handling, loading docks, forklifts, machinery and conveyors, material storage, hazard communication, charging stations, and poor ergonomics, offering best practice actions to help create a safer workplace.

Unit 4 – Quiz

The course concludes with a 15-question multiple-choice quiz. A score of 80% or higher is required to earn your Echo3 Warehouse Safety certificate. You can retake the quiz if needed.

Warehouse Safety Course Certificate

Download and Print Your Certificate

- Written in compliance with the various UK Regulations that apply to working in warehouses.

- Developed by qualified health and safety professionals

- Accredited by CPD – learn more about CPD here

- Last Updated June 2024

- To gain the certificate you must complete the assessment which involves 10 questions.

- The online Warehouse Safety certificate is valid for 3 years.

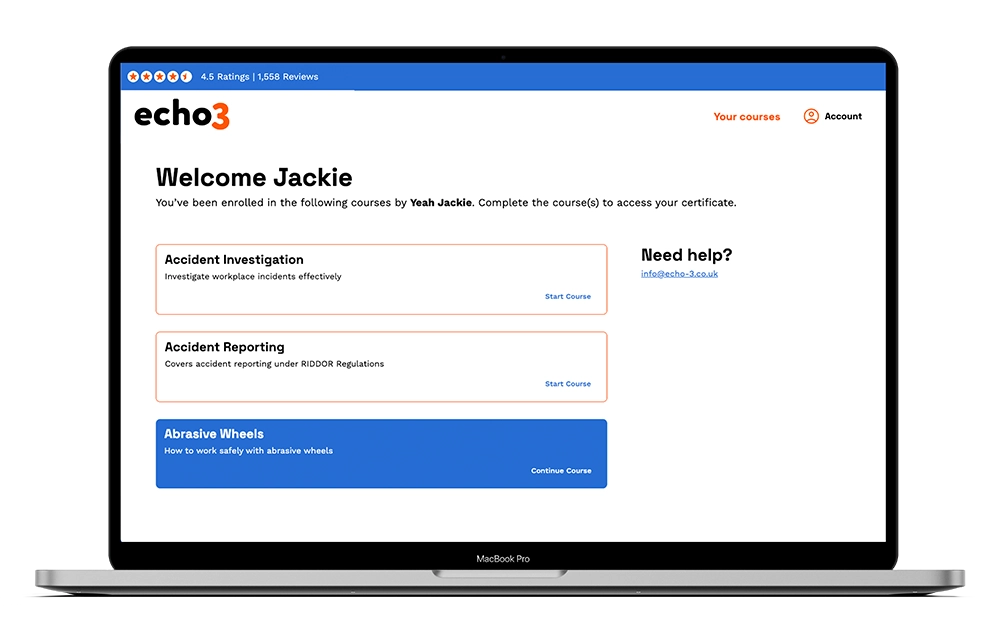

Course Preview

Echo3 courses include engaging motion-graphic video content, with full english subtitles

Reviews

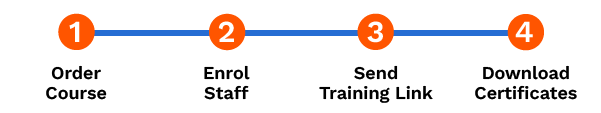

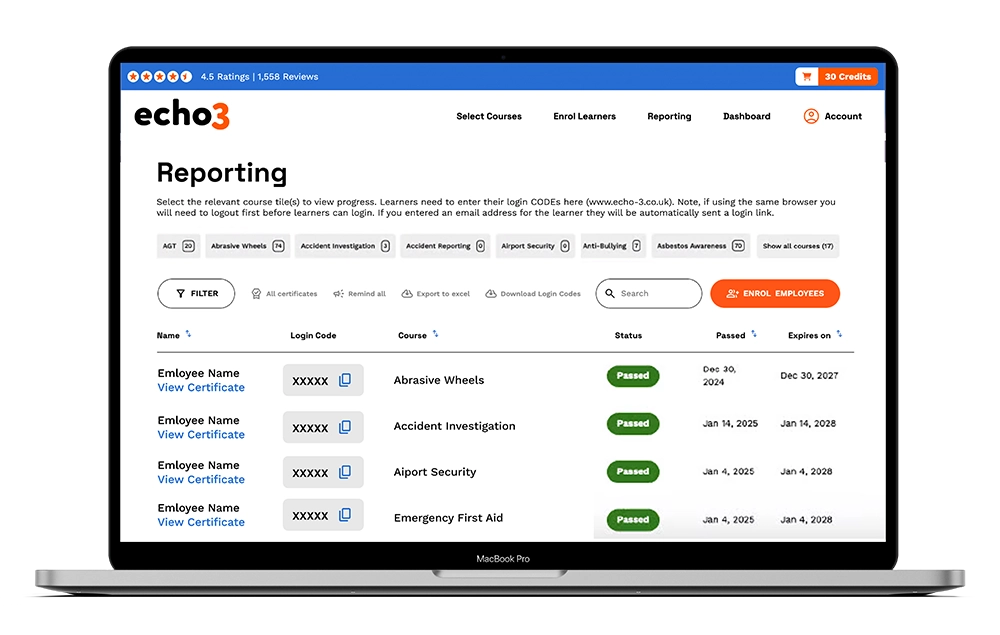

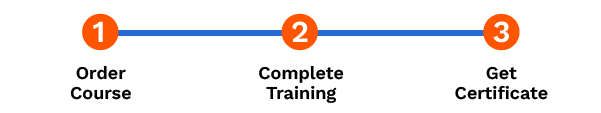

How to Get Certified in 3 Steps

Individual Learners

Benefits for Individuals

-

Engaging video-based content

-

Learner dashboard included

-

Instant access after payment

-

Free course retakes

-

Shareable digital certificate

QR Code Certificate

QR Code Certificate

Bulk Buying Discounts

What are the objectives of warehouse safety training?

The course objectives include;

The course objectives include;

Promote a culture of safety and reduce the risk of workplace accidents within warehouse environments.

Educate participants on essential safety principles, including hazard recognition, risk assessment, and emergency response.

Enhance compliance with relevant regulations and industry standards, equipping employers with an effective training and reporting tool.

Who should received warehouse safety training?

The Echo3 Warehouse Safety training has been designed for;

All Warehouse Operatives – benefit from understanding common warehouse hazards and how to stay safe.

Supervisors and Managers – benefit by understanding best-practice safety-protocols to keep in place.

New & Experienced Staff – The Warehouse Safety course is recommended to new staff as part of their induction. And also to staff who haven’t received warehouse safety training for 3 years or more.

What are the learning outcomes of this course?

The Echo3 Online Warehouse Safety course imparts crucial knowledge to enhance workplace safety. Participants can expect to grasp fundamental principles of warehouse safety, including hazard identification and risk assessments.

The Echo3 Online Warehouse Safety course imparts crucial knowledge to enhance workplace safety. Participants can expect to grasp fundamental principles of warehouse safety, including hazard identification and risk assessments.

Learners will gain insights into proper storage and material handling techniques. Additionally, the course covers the importance of personal protective equipment (PPE).

Upon completion, participants will be equipped to recognise and mitigate potential risks, creating a safer warehouse environment for themselves and colleagues.

Are warehouse safe places to work?

From recent UK government published RIDDOR statistics we know 3.1% of warehouse workers suffer from work-related ill health while the fatality rate in the Transport and Storage sector was around twice that of all industries combined.

Vehicle collisions caused 37% of the Transport and Storage sector fatalities.

Of the work-related ill health, Manual Handling and Slips, Trips & Falls were the two biggest contributors, together causing 54% of the total.

2023 UK RIDDOR statistics for the Transport and Storage industry.

Because of the greater risks present in warehouses it is reasonable that there is a greater level of safety training.

Your risk assessments will determine the appropriate training based on specific hazards.

What are topical unsafe behaviours in warehouses?

Unsafe behaviours increase the risk of warehouse accidents. Common unsafe behaviours include:

- Improper use of forklifts

- Improper stacking

- Horseplay

- Inadequate fire safety provisions

- Improper Personal Protective Equipment

- Repetitive and/or heavy lifting

Pallet Stacking Hazard

Forklift Incident

What are some warehouse safety tips?

The UK Health & Safety executive has created a guide to safety in warehouses which you may find helpful. You may also wish to consider:

RIDDOR statistics show Slips & Trips are the most common cause of ‘serious injury’ in warehouses. While Manual Handling accounts for 45% of ‘over 3 days injuries.

With regards to Slips & Trips;

- Firstly, ensure flooring doesn’t become contaminated. E.g. ensure sensible packing of materials.

- Secondly, when contamination does happen, deal with it immediately. Ideally by cleaning. Signs should be only a very temporary measure.

- Thirdly, keep floors and traffic routes free from obstructions

- Fourthly, using correct footwear can help reduce slips

- Next, if possible, install slips resistant flooring. Prioritise steps.

- Furthermore, adequate lighting can help reduce slips

With regards to Manual Handling.

- Firstly, try to avoid the task first

- Secondly, supply mechanical aids

- Thirdly, provide specific Manual Handling training

- In addition, encourage staff to suggest improvements