Temperature Control Course

The Echo3 Temperature Control course goes beyond legal requirements to explain the “why” behind temperature rules and how to apply them effectively — whether you’re running a small café, a high-volume restaurant, or a large-scale catering operation.

Effective temperature management is a cornerstone of food safety in any commercial kitchen. It plays a vital role in preventing foodborne illnesses and protecting both your customers and your business.

Although customers may never see the checks happening behind the scenes, precise temperature control is the foundation of safe food service. It ensures compliance, reduces risk, and builds trust.

In the UK, over 2.4 million cases of foodborne illness occur each year — and poor temperature control is one of the leading causes. The good news? These incidents are entirely preventable with the right knowledge and procedures.

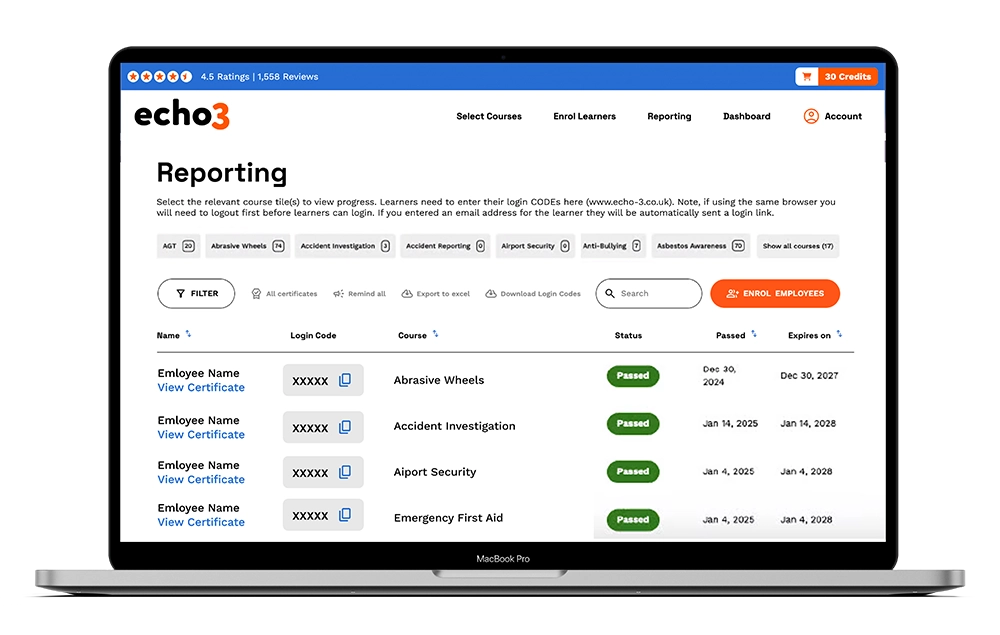

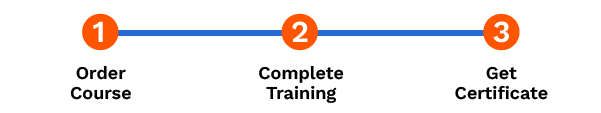

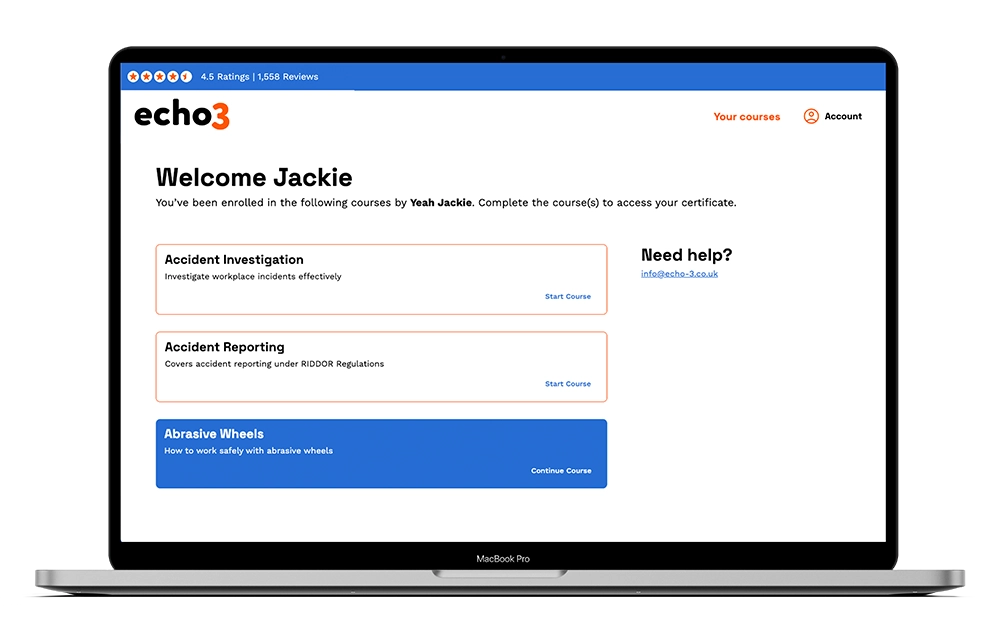

You can purchase the course for individual use or choose the Team option to assign training to staff members. Upon completion, learners receive a downloadable Echo3 Temperature Control Certificate, perfect for maintaining up-to-date training records.

Unit 1 – Legal Framework:

This unit introduces the course and explores the legal foundations of food safety, including the Food Safety Act 1990, the Food Safety and Hygiene (England) Regulations 2013, and the Food Safety and Hygiene (Scotland) Regulations 2006.

Unit 2 – Temperature Fundamentals:

This unit focuses on understanding food safety temperatures, including the concept of the danger zone (8°C to 63°C), the 2-hour/4-hour rule, common mistakes related to temperature control, and safe practices to minimise risks associated with the danger zone.

Unit 3 – Equipment and Monitoring:

This unit covers the different types of thermometers used in food safety, their proper use and maintenance, including calibration procedures, as well as the documentation requirements necessary for effective temperature monitoring and compliance.

Unit 4 – Storage Equipment:

This unit explores various types of storage equipment essential for food safety, including refrigerators, freezers, hot holding equipment, and display units, concluding with a summary of key points and best practices for the effective use of all equipment.

Unit 5 – Temperature Control Procedures:

This unit covers essential procedures for effective temperature control, including cooling and chilling methods, the use of blast chillers as a professional solution, alternative cooling techniques, as well as heating and hot holding practices, their specific requirements, and common pitfalls with practical solutions.

Unit 6 – Special Considerations:

This unit focuses on the safe handling of high-risk foods, with particular attention to raw meat, fish, and eggs, highlighting the specific precautions needed to prevent cross-contamination and ensure food safety.

Unit 7 – Operations:

This unit examines the importance of effective transport and delivery management in maintaining food safety standards throughout the supply chain.

Unit 8 – Compliance:

This final unit covers key aspects of compliance and documentation, the role of enforcement and inspections, and concludes the course by reinforcing the importance of adhering to food safety regulations and best practices.

Temperature Control Certificate

Download and Print Your Certificate

- Written in compliance with the The Food Safety Act 1990

- Developed by qualified health and safety professionals

- Last Updated August 2025

- To gain the certificate you must complete the assessment which involves 15 questions.

- The online Temperature Control certificate is valid for 3 years.

Course Preview

Echo3 courses include engaging motion-graphic video content, with full english subtitles

Reviews

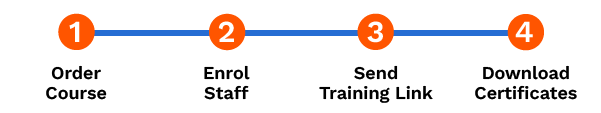

How to Get Certified in 3 Steps

Individual Learners

Benefits for Individuals

-

Engaging video-based content

-

Learner dashboard included

-

Instant access after payment

-

Free course retakes

-

Shareable digital certificate

QR Code Certificate

QR Code Certificate

Bulk Buying Discounts

What are the course objectives?

- Reduce the chance foodborne illnesses due to poor temperature controls

- Provide food business owners, managers and staff keep consumers safe by providing a clear understanding of how to maintain safe food temperatures

- Provide food business owners, managers and staff with the knowledge need to comply with UK food safety regulations across all the home nations.

- Provide an awareness danger zone mistakes to lower the chance of them being repeated in your workplace

What is the temperature danger zone?

Poor temperature control is the most common cause of food poisoning outbreaks. In the danger zone (8°C to 63°C), here’s what’s happening:

- Bacteria can double every 20-30 minutes

- A single bacterium could become over 1 million in just 8 hours

- Most harmful bacteria love temperatures around 37°C (body temperature)

The riskiest temperatures are between 20°C to 50°C – this is room temperature to warm. Think about a buffet on a summer day, or food left out on a counter.

What is the “2-hour/4-hour Rule?

This is your emergency guide when things don’t go to plan:

- 0-2 hours in danger zone: Food can still be used safely

- 2-4 hours in danger zone: Use immediately – don’t try to cool and store it

- Over 4 hours in danger zone: Discard immediately

Practical example: Your refrigerator breaks down on a Saturday morning. You discover it 3 hours later when you arrive for lunch prep. The food has been at 15°C for 3 hours. According to the rule, you must use this food immediately for service – you cannot cool it down and save it for later.

This rule is particularly important for hot holding. Food which will be served hot may be kept on display out of temperature control for a single period of two hours. After this time, food must be discarded, reheated properly, or cooled quickly.

What documentation is required?

Record Keeping – Your Legal Protection – Think of documentation as your insurance policy – it proves you’ve done everything right when questions come up.

Temperature Logs

Your daily records need equipment ID (“Fridge #1”), date, time, temperature, who checked it, and any corrective actions taken. These need to be taken a minimum of twice a day.

Corrective Action Records

When temperatures go out of range, document what went wrong and when, which food was affected, immediate actions taken, how you fixed the problem, prevention steps, and follow-up monitoring results.

Maintenance Records

Keep track of equipment servicing, thermometer calibrations, cleaning schedules, staff training dates, and supplier audits. These show you’re managing everything systematically.

Staff Training Records

Document all food safety training from initial induction through refresher courses, including specific temperature control training, certification dates, renewals, and training effectiveness. This shows you’re serious about ensuring people actually learned what they needed to know

Related Courses

To gain access to all these courses you can also order Echo3 Credit.